Project Budget

$110 M

Architect

Liminal Architecture, WOHA

Developer

University of Tasmania

General Contractor & Client

Hansen Yuncken

Year

2013 – 2019

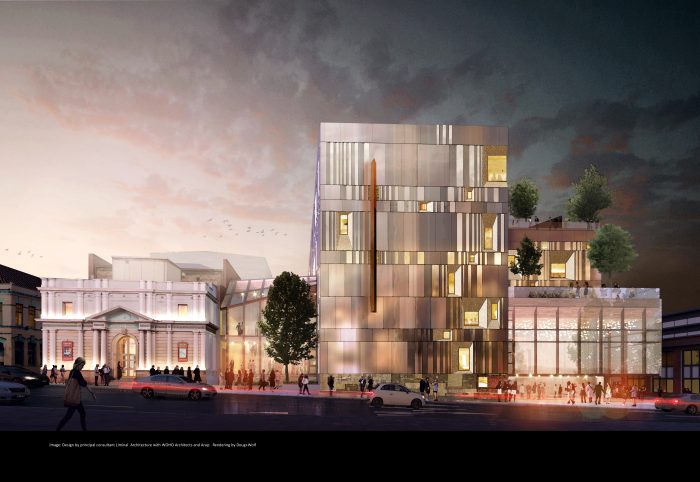

Image courtesy of LIMINAL Studio

Structural Design, BIM Consulting

Gandy & Roberts

Building Services

JMG

Theatre & Acoustic Design

ARUP

Image courtesy of LIMINAL Studio

Project brief

BIM Consulting, Coordination and Management provided to the design team. Establishing BIM Execution guidelines and produce LOD300 models of the base building objects for handover to the general contractor.

Description

The final building provides improvements to the Theatre Royal, and a new University Conservatorium of Music; it will include new performance venues, public spaces and an international research institute.

Before the BIM coordination and LOD300 delivery process started during construction documentation, design collaboration & coordination was largely conducted through exchange of 2D CAD drawings.

The general contractor commissioned the design team to provide design models to LOD300 as part of construction documentation. The BIM Consulting team from Gandy & Roberts negotiated the collaboration procedures within the design team, as well as the model deliverables with the client.

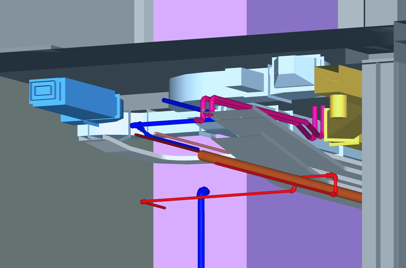

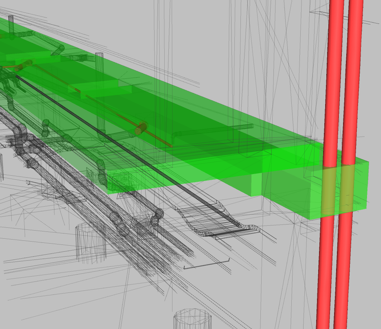

The main tool for model coordination was Navisworks©. All design models were checked visually for consistency. The Navisworks clash detective was used to identify clashes between critical model objects. Coordination and clash reports were issued to all project stakeholders in Navisworks© NWD and HTML format.

Challenges

- Consideration of different design software platforms (Revit, Archicad).

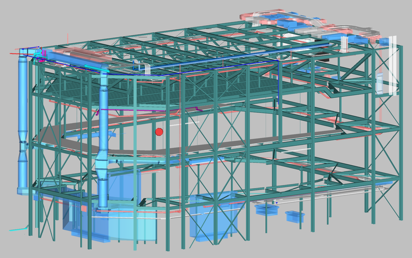

- Incorporation of 8 main design models from 4 consultants.

- Inexperience of design team parties in LOD300 BIM deliveries.

- Setup of BIM protocols and significant design changes late in the design process.

- Very complex and irregular building with several acoustically detached sub-structures within the main building.

- Tight services corridors.

- Design team members in remote locations (Singapore, Melbourne, Hobart).

- Incremental issue of individual LOD300 models to meet program requirements.

Results & Achievements

In consideration of the capabilities of all project team members and used software platforms, procedures were developed to facilitate an effective model-based collaboration within the design team. The procedures were implemented by Gandy & Roberts’ BIM Consulting Team successfully through provision of manuals, short videos, workshops and 1 on 1 training sessions.

Many industry leaders are suggesting that BIM must be implemented at an early stage of a project to be successful and effective. BIM on The Hedberg has proven that this is a misconception and that coordinated BIM can be implemented successfully at any stage, even when design models are already well established and not setup with coordinated BIM in mind.

More than 20 individual steelwork, precast, in-situ concrete, building services and CLT (Cross Laminated Timber) models were handed over to the client and provided to the shop detailers for fabrication and installation. The provision of these accurate setout models resulted in a reduction of the shop drawing turnaround for CLT Panels from 6 weeks to 2 weeks. It was suggested that the steelwork detailer was able to gain significant efficiencies as well.

UTAS Performing Arts and Creative Industries Centre

BIM Coordination was finalised and LOD300 models were delivered within budget. Despite exceeding the LOD300 delivery program significantly due to unexpected design changes late in the process.

The BIM coordination process uncovered many critical building design issues which had been missed using traditional plan-based coordination. It also allowed to design more efficient services routing solutions and a more cost effective structural design.

UTAS Performing Arts and Creative Industries Centre

The application of coordinated BIM with LOD300 models as a product, helped to identify most design issues before they could cause delays and variations during construction. This reduced critical program and budgetary risks for contractor, client and designers.

The Hedberg BIM process has been presented by the design team and the main contractor at HobartBIM as a feature project, and is the largest development in Tasmania where integrated BIM has been implemented during design and construction at the time.

UTAS Performing Arts and Creative Industries Centre

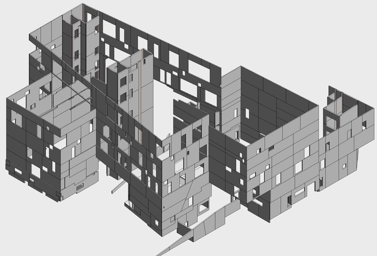

LOD300 Model Handover: Full Precast Concrete Model

UTAS Performing Arts and Creative Industries Centre

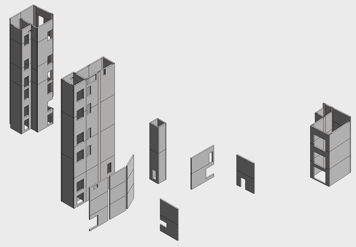

LOD300 Model Handover: Precast Shear & Core Model

UTAS Performing Arts and Creative Industries Centre

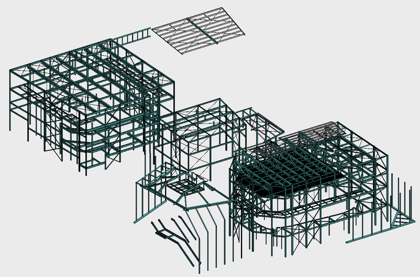

LOD300 Model Handover: Combined Steelwork Model

UTAS Performing Arts and Creative Industries Centre

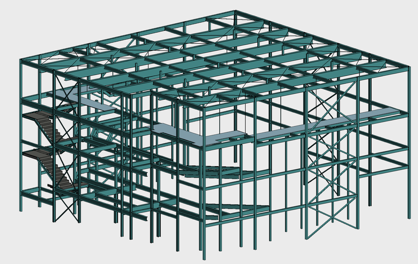

LOD300 Model Handover: Steelwork Studio Theatre

UTAS Performing Arts and Creative Industries Centre